Image copyright

Image copyright

BSI/University of Nottingham

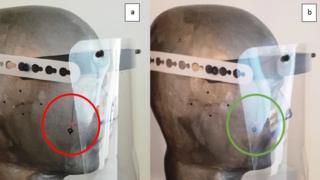

This face shield is made from perspex, but was A4-sized and failed to offer sufficient protection from the side.

The British Standards Institution (BSI) says that A4-sized face shields do not always protect healthcare workers’ faces from exposure to Covid-19.

Faced with a shortage of personal protective equipment (PPE), many communities have started making their own to help frontline workers.

These include 3D-printing and laser-cut designs.

Some incorporate A4-sized acetate transparent paper, designed for overhead projectors, to make the visor.

“People are trying to use materials that are readily available,” said Nathan Shipley, PPE group certification manager at the BSI.

“Using acetates from an overhead projector is a quick fix, but the width of the acetate screens isn’t wide enough.

“Some people say, ‘any PPE is better than no PPE’, but if you are wearing something you think will protect you and it won’t, you are in more danger.”

The BSI looks at three key areas when testing PPE face shields:

- How clear the visor is to look through

- The dimension of the headband – to minimise pressure headaches

- The area of coverage – how far around the face is protected from droplets or splatter

It follows the European standard EN166, which determines the size of the face area that needs protection – although some women find that standard issue kit doesn’t fit them.

The BSI said it has approved 21 face shield designs so far and has received around 70 from various groups, including businesses, academic institutions and individuals.

It aims to carry out tests within two or three days, and if a CE number is granted, signifying that it has passed European safety standards – it is for the duration of the pandemic, and not permanent.

Image copyright

University of Nottingham

The University of Nottingham face shield now has its own CE number to show it meets European safety standards

The Royal Mint and the University of Nottingham were the first to get regulatory approval.

“We wanted to make sure we were providing something that was safe,” said Professor Richard Hague at the university’s Faculty of Engineering.

Prof Hague said the process took around 10 days – because the original design also fell foul of the A4 width issue.

The university is now in the process of delivering 5,000 face shields to the NHS in Nottingham.

“This is not a hard thing to do – it’s using a system we have to make a product that’s needed,” said Prof Hague.

More Stories

What Makes Genuine Canon Ink Cartridges A Great Buy?

Computer Futures – Right Strategy to Let You Know Cloud Computing Technology

How Can I Watch Satellite TV On My Computer